Plum-shaped elastic coupling

Diaphragm coupling

Universal coupling

Tyre coupling

Slider coupling

Rigid coupling

Star-shaped (shaped) elastic coupling

Drum gear coupling

Elastic sleeve pin coupling

Elastic pin coupling

Elastic pin gear coupling

Roller chain coupling

Various coupling accessories

Water pump coupling

Expansion sleeve

Rack series

Website: www.rigid-shaft-coupling.xyz

Address: Xihuan Industrial Zone, Botou City, Hebei Province

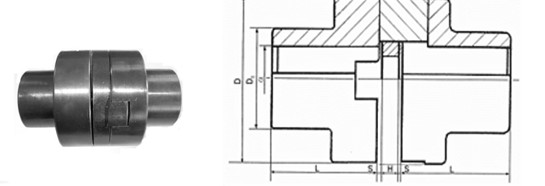

SL cross slider coupling

SLOldham couplingAlso known as the metal slider coupling, the slider is ring-shaped and made of steel or wear-resistant alloy. It is suitable for transmissions with low speed and large transmission torque.

The SL cross slider coupling is also known as the metal slider coupling. It consists of two half couplings with radial grooves on the end faces and a middle slider with a tenon at each end. The two ends of the middle slider are The tenons are perpendicular to each other, and they are respectively embedded in the grooves of the two half couplings to form a moving pair. If the measuring axis is not concentric or skewed, the slider will slide in the groove during movement, so the groove and the slider Lubricant should be added to the working surface of the shaft. If the two shafts are not concentric, when the speed is high, the eccentricity of the slider will produce a lot of centrifugal force wear and bring additional load to the shaft and shaft. Therefore, it is only suitable for low speed and transmission Large load occasions.

The SL cross slider coupling is noisy, low in efficiency, and wears quickly. Generally, it is not used as much as possible. It is only used when the speed is very low, such as ball mills.Allowable compensation amount: axial △ x=1~2mm, radial △ y ≤ 0.04d (d is shaft diameter), angular △α≤ 40 ′The speed generally does not exceed 300r/min.

| Basic parameters of SL cross slide coupling (Q/JL03-2001): | ||||||||||

| specification | Nominal torque Tn(N·M) | Permissible speed | Diameter of shaft hole | D | D1 | L | H | S | Moment of inertia (kg.m 2) | Weight (kg) |

| [n]r/min | d | |||||||||

| SL70 | 120 | 250 | 15 ~ 18 | 70 | 32 | 42 | 14 | 0.5 | 0.002 | 1.5 |

| SL90 | 250 | 250 | 20 ~ 30 | 90 | 45 | 52 | 14 | 0.008 | 2.6 | |

| SL100 | 500 | 250 | 36 ~ 40 | 100 | 60 | 70 | 19 | 0.026 | 5.5 | |

| SL130 | 800 | 250 | 45 ~ 50 | 130 | 80 | 90 | 19 | 0.07 | 10 | |

| SL150 | 1250 | 250 | 55 ~ 60 | 150 | 95 | 112 | 19 | 0.14 | 15.5 | |

| SL170 | 2000 | 250 | 65 ~ 70 | 170 | 105 | 125 | 24 | 0.25 | 22.4 | |

| SL190 | 3200 | 250 | 75 ~ 80 | 190 | 110 | 140 | 29 | 0.5 | 31.5 | |

| SL210 | 5000 | 250 | 85 ~ 90 | 210 | 130 | 160 | 33 | 1 | 0.9 | 45 |

| SL240 | 8000 | 250 | 95 ~ 100 | 240 | 140 | 180 | 33 | 1.6 | 59.5 | |

| SL260 | 9000 | 250 | 100 ~ 110 | 260 | 160 | 190 | 33 | 2 | 76 | |

| SL280 | 10000 | 100 | 110 ~ 120 | 280 | 170 | 200 | 33 | 3 | 94.3 | |

| SL300 | 13000 | 100 | 120 ~ 130 | 300 | 180 | 210 | 43 | 4.3 | 111 | |

| SL320 | 16000 | 100 | 130 ~ 140 | 320 | 190 | 220 | 43 | 5.7 | 129 | |

| SL340 | 20000 | 100 | 150 | 340 | 210 | 250 | 48 | 8.4 | 162 | |

| SL360 | 32500 | 100 | 160 | 360 | 240 | 280 | 48 | 19.2 | 258 | |

| SL400 | 38700 | 80 | 170 | 400 | 260 | 300 | 48 | 26.1 | 305 | |

| SL460 | 63000 | 70 | 200 | 460 | 300 | 350 | 58 | 62.9 | 560 | |