Plum-shaped elastic coupling

Diaphragm coupling

Universal coupling

Tyre coupling

Slider coupling

Rigid coupling

Star-shaped (shaped) elastic coupling

Drum gear coupling

Elastic sleeve pin coupling

Elastic pin coupling

Elastic pin gear coupling

Roller chain coupling

Various coupling accessories

Water pump coupling

Expansion sleeve

Rack series

Website: www.rigid-shaft-coupling.xyz

Address: Xihuan Industrial Zone, Botou City, Hebei Province

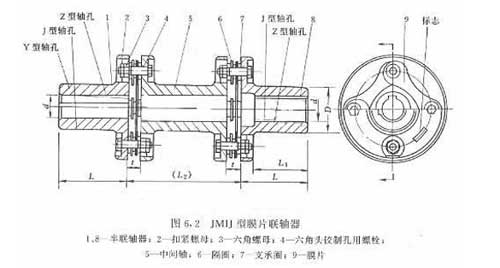

JMIJ to intermediate shaft diaphragm coupling

Before installing the JMIJ to the intermediate shaft diaphragm coupling, check whether the prime mover and the working machine are concentric, whether there are wrapping paper and scratches on the surfaces of the two shafts, and whether there is debris in the inner holes of the two half couplings of the coupling. , Whether there are bruises on the edge of the inner hole, if any, the shaft and half coupling should be cleaned up, and the bruises should be treated with a fine file.Then check whether the inner hole diameter and length of the two half couplings are consistent with the diameter and shaft elongation of the prime mover and working machine.In general selection, it is better to let the length of the prime mover and the working machine end half coupling be less than the shaft extension of 10-30mm.In order to facilitate the installation of the JMIJ to the intermediate shaft diaphragm coupling, it is good to put the two half couplings in the 120-150 incubator or oil tank for preheating, so that the inner hole size increases and it is easy to install.

1. Before installation, check whether the prime mover and working machine shafts are concentric, whether there are wrapping paper and scratches on the surfaces of the two shafts, whether there are sundries in the inner holes of the two half couplings of the coupling, and whether there is any edge of the inner hole. If there are bruises, the shaft and half coupling should be cleaned up, and the bruises should be treated with a fine file.Then check whether the inner hole diameter and length of the two half couplings are consistent with the diameter and shaft elongation of the prime mover and working machine.In general selection, it is better to let the length of the prime mover and the working machine end half coupling be less than the shaft extension of 10-30mm.

2. In order to facilitate the installation, it is better to put the two half couplings in the 120-150 incubator or oil tank for preheating, so that the inner hole size increases and it is easy to install.After installation, ensure that the shaft head cannot protrude from the end face of the half coupling, and it is better to be flush.Detect the distance between the two halves of the coupling: take the average of the readings of 3 to 4 points measured along the two inner sides of the flange of the half coupling, and the sum of the measured dimensions of the extension and the two diaphragm sets, two The error is controlled within the range of 0-0.4mm.

3. Alignment: Use a dial indicator to detect the runout of the flange end face and outer circle of the two halves of the coupling flange. When the outer circle of the flange is less than 250mm, the runout value should not be greater than 0.05mm; when the outer circle of the flange is greater than 250mm , The runout value should not be greater than 0.08. High-speed, high-torque shafting transmission.As well as the shaft transmission of various mechanical devices with little change in load, it is extremely versatile.

The basic parameters and main dimensions of the JMIJ intermediate shaft diaphragm coupling mm (JB/T 9147-1999)

| model | Nominal torque Tn /Nm |

Instantaneous high torque Tmax /Nm |

Permissible speed [n] /r.min -1 |

Diameter of shaft hole d(H 7) | Shaft hole shaft hole shaft hole shaft hole | D | t | L2 | Moment of inertia I/kg.m 2 ≈ | Mass m/kg ≈ | |||

| Y type | J, J1, Z, Z1 type | L recommended | |||||||||||

| L | L | L1 | |||||||||||

| JMIJ1 | 25 | 80 | 6000 | 14 | 32 | - | J1 type is 27 Z1 type is 20 | 35 | 90 | 8.8 | 100 | 0.0013 | 1.8 |

| 16, 18, 19 | 42 | 30 | |||||||||||

| 20, 22 | 38 | ||||||||||||

| JMIJ2 | 63 | 180 | 5000 | 18, 19 | 42 | - | 30 | 45 | 100 | 9.5 | 100 | 0.002 | 2.4 |

| 20, 22, 24 | 52 | 38 | |||||||||||

| 25 | 62 | 44 | |||||||||||

| JMIJ3 | 100 | 315 | 5000 | 20, 22, 24 | 52 | - | 38 | 50 | 120 | 11 | 120 | 0.0047 | 4.1 |

| 25, 28 | 62 | 44 | |||||||||||

| 30 | 82 | 60 | |||||||||||

| JMIJ4 | 160 | 500 | 4500 | 24 | 52 | - | 38 | 55 | 130 | 12.5 | 120 | 0.0069 | 5.4 |

| 25, 28 | 62 | 44 | |||||||||||

| 30, 32, 35 | 82 | 60 | |||||||||||

| JMIJ5 | 250 | 710 | 4000 | 28 | 62 | - | 44 | 60 | 150 | 14 | 140 | 0.0153 | 8.8 |

| 30-32-35 | 82 | 60 | |||||||||||

| 40 | 112 | 84 | |||||||||||

| JMIJ6 | 400 | 1120 | 3600 | 32, 35, 38 | 82 | 82 | 60 | 65 | 170 | 15.5 | 140 | 0.0281 | 13.4 |

| 40, 42, 45, 48, 50 | 112 | - | 84 | ||||||||||

| JMIJ7 | 630 | 1800 | 3000 | 40, 42 | 112 | 112 | 84 | 70 | 210 | 19 | 150 | 0.076 | 22.3 |

| 45, 48, 50, 55, 56 | |||||||||||||

| 60 | 142 | 107 | |||||||||||

| JMIJ8 | 1000 | 2500 | 2800 | 45, 48 | 112 | 112 | 84 | 80 | 240 | 22.5 | 180 | 0.1602 | 36 |

| 50, 55, 56 | |||||||||||||

| 60-63-65 | 142 | 107 | |||||||||||

| JMIJ9 | 1600 | 4000 | 2500 | 55, 56 | 112 | 112 | 84 | 85 | 260 | 24 | 220 | 0.2509 | 48 |

| 60, 63, 65, 70, 71, 75 | 142 | 107 | |||||||||||

| 80 | 172 | 132 | |||||||||||

| JMIJ10 | 2500 | 6300 | 2000 | 63, 65, 70, 71, 75 | 142 | 142 | 107 | 90 | 280 | 17 | 250 | 0.5195 | 85 |

| 80-85-90 | 172 | - | 132 | ||||||||||

| JMIJ11 | 4000 | 9000 | 1800 | 75 | 142 | 142 | 107 | 95 | 300 | 19.5 | 290 | 0.8223 | 112 |

| 80-85-90 | 172 | 172 | 132 | ||||||||||

| 100, 110 | 212 | - | 167 | ||||||||||

| JMIJ12 | 6300 | 12500 | 1600 | 90, 95 | 172 | 132 | 120 | 340 | 23 | 300 | 1.4109 | 152 | |

| 100-110-120 | 212 | 167 | |||||||||||