Plum-shaped elastic coupling

Diaphragm coupling

Universal coupling

Tyre coupling

Slider coupling

Rigid coupling

Star-shaped (shaped) elastic coupling

Drum gear coupling

Elastic sleeve pin coupling

Elastic pin coupling

Elastic pin gear coupling

Roller chain coupling

Various coupling accessories

Water pump coupling

Expansion sleeve

Rack series

Website: www.rigid-shaft-coupling.xyz

Address: Xihuan Industrial Zone, Botou City, Hebei Province

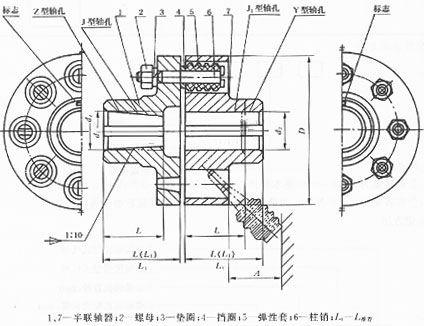

TL type elastic sleeve pin coupling

TL type elastic sleeve pin coupling uses a pin with an elastic sleeve (rubber material) at one end, which is installed in the flange hole of the two halves of the coupling to realize the connection of the two halves of the coupling.

TL type elastic sleeve pin coupling has a relatively simple structure, easy to manufacture, no lubrication, no need to bond with metal vulcanization, easy to replace the elastic sleeve, no need to move the half coupling, with compensation for the relative deviation of the two shafts and damping buffer performance.The elastic sleeve works by compression and deformation. Because the thickness of the elastic sleeve is thin, the volume is small, and the elastic deformation is limited, the elastic sleeve pin coupling can compensate the axis displacement and elasticity, but the allowable compensation amount for the axis displacement is less. The elasticity is weak.

The elastic sleeve pin coupling relies on the locking force of the pin group to generate the friction torque on the contact surface, and compress the rubber elastic sleeve to transmit the torque.It is suitable for small and medium-power shafting transmissions with good rigidity of the installation base, high centering accuracy, low impact load, and low vibration reduction requirements.

Basic performance parameters and main dimensions of TL elastic sleeve pin coupling

| model | Nominal torque | Permissible speed | Diameter of shaft hole | Length of shaft hole | Main dimensions | weight | |||

| Tn | [n] | d,d1,dz | Y | J, J1, Z | D | S | A | kg | |

| nm | r / min | L | L1 | ||||||

| TL1 | 6.3 | 8800 | 9 ~ 14 | 20 ~ 32 | 14 ~ 20 | 71 | 3 | 18 | 1.2 |

| TL2 | 16 | 7600 | 12 ~ 19 | 32 ~ 42 | 20 ~ 42 | 80 | 3 | 18 | 1.64 |

| TL3 | 31.5 | 6300 | 16 ~ 25 | 42 ~ 62 | 30 ~ 62 | 95 | 4 | 35 | 4.9 |

| TL4 | 63 | 5700 | 20 ~ 32 | 52 ~ 82 | 38 ~ 82 | 106 | 4 | 35 | 2.4 |

| TL5 | 125 | 4600 | 25 ~ 40 | 62 ~ 112 | 44 ~ 112 | 130 | 5 | 45 | 8.36 |

| TL6 | 250 | 3800 | 32 ~ 50 | 82 ~ 112 | 60 ~ 112 | 160 | 5 | 45 | 10.36 |

| TL7 | 500 | 3600 | 40 ~ 65 | 112 ~ 142 | 84 ~ 142 | 190 | 5 | 45 | 15.6 |

| TL8 | 710 | 3000 | 45 ~ 80 | 112 ~ 172 | 84 ~ 172 | 224 | 6 | 65 | 25.4 |

| TL9 | 1000 | 2850 | 50 ~ 85 | 112 ~ 172 | 84 ~ 172 | 250 | 6 | 65 | 30.9 |

| TL10 | 2000 | 2300 | 63 ~ 120 | 142 ~ 212 | 107 ~ 212 | 315 | 8 | 80 | 65.9 |

| TL11 | 4000 | 1800 | 80 ~ 140 | 172 ~ 252 | 132 ~ 252 | 400 | 10 | 100 | 122.6 |

| TL12 | 8000 | 1450 | 100 ~ 180 | 212 ~ 302 | 167 ~ 302 | 475 | 12 | 130 | 218.4 |

| TL13 | 16000 | 1150 | 120 ~ 220 | 212 ~ 352 | 167 ~ 352 | 600 | 14 | 180 | 425.8 |