Plum-shaped elastic coupling

Diaphragm coupling

Universal coupling

Tyre coupling

Slider coupling

Rigid coupling

Star-shaped (shaped) elastic coupling

Drum gear coupling

Elastic sleeve pin coupling

Elastic pin coupling

Elastic pin gear coupling

Roller chain coupling

Various coupling accessories

Water pump coupling

Expansion sleeve

Rack series

Website: www.rigid-shaft-coupling.xyz

Address: Xihuan Industrial Zone, Botou City, Hebei Province

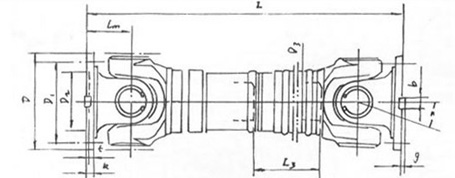

Short telescopic welded universal coupling

Short stretchWelded universal couplingIt is a commonly used coupling.Utilizing the characteristics of its structure, it can make two shafts that are not on the same axis or that have a large angle of axis or that have a large axial movement continuously rotate at equal angular speed, and reliably transmit torque and motion.It can be widely used in metallurgy, lifting, engineering transportation, mining, petroleum, shipbuilding, coal, rubber, papermaking machinery and other heavy machinery industries to transmit torque in mechanical shafting.

The main features of the short telescopic welded universal coupling are:

1. Has a large angle compensation capability.

2. The structure is compact and reasonable. The SWC-DH type adopts an integral fork to make the carrier reliable.

3. Large carrying capacity.Compared with other types of couplings with the same rotating diameter, the torque transmitted by it is larger. This is superior to the range of matching mechanical equipment with restricted rotating diameter.

4. High transmission efficiency.Its transmission efficiency is 98-99.8%, and it is used for high-power transmission with obvious energy-saving effect.

5. Stable transportation, low noise, easy assembly and disassembly and maintenance.

Basic parameters and main dimensions of short telescopic welded universal joint

| model | turn around 直径 D |

Nominal torque Tn /Nm |

Fatigue torque Tf kN.m |

Axis angle β |

Stretch Ls |

Size | Rotation penetration I kg·m2 | Mass G kg | |||||||||||

| Lmin | D1 (js11) |

D2 (H7) |

D3 | Lm | nd | k | t | b (h9) |

g | Lmin | increase 100 mm |

Lmin | increase 100 mm |

||||||

| SWC180DH1 | 180 | 12.5 | 6.3 | ≤25 | 75 | 650 | 155 | 105 | 114 | 110 | 8-17 | 17 | 5 | - | - | 0.165 | 0.0070 | 58 | 2.8 |

| SWC180DH2 | 55 | 600 | 0.162 | 56 | |||||||||||||||

| SWC180DH3 | 40 | 550 | 0.160 | 52 | |||||||||||||||

| SWC225DH1 | 225 | 40 | 20 | ≤15 | 85 | 710 | 196 | 135 | 152 | 120 | 8-17 | 20 | 5 | 32 | 9.0 | 0.415 | 0.0234 | 95 | 4.9 |

| SWC225DH2 | 70 | 640 | 0.397 | 92 | |||||||||||||||

| SWC250DH1 | 250 | 63 | 31.5 | ≤15 | 100 | 795 | 218 | 150 | 168 | 140 | 8-19 | 25 | 6 | 40 | 12.5 | 0.900 | 0.0277 | 148 | 5.3 |

| SWC250DH2 | 70 | 735 | 0.885 | 136 | |||||||||||||||

| SWC180DH1 | 285 | 90 | 45 | ≤15 | 120 | 950 | 245 | 170 | 194 | 160 | 8-21 | 27 | 7 | 40 | 15.0 | 1.876 | 0.0510 | 229 | 6.3 |

| SWC180DH1 | 80 | 880 | 1.801 | 221 | |||||||||||||||

| SWC180DH1 | 315 | 125 | 63 | ≤15 | 130 | 1070 | 280 | 185 | 219 | 180 | 10-23 | 32 | 8 | 40 | 15.0 | 3.331 | 0.0795 | 346 | 8.0 |

| SWC180DH1 | 90 | 980 | 3.163 | 334 | |||||||||||||||

| SWC180DH1 | 350 | 180 | 90 | ≤15 | 140 | 1170 | 310 | 210 | 267 | 194 | 10-23 | 35 | 8 | 50 | 16.0 | 6.215 | 0 2219 .. | 508 | 15.0 |

| SWC180DH1 | 90 | 1070 | 5.824 | 485 | |||||||||||||||

| SWC180DH1 | 390 | 250 | 125 | ≤15 | 150 | 1300 | 345 | 235 | 267 | 215 | 10-25 | 40 | 8 | 70 | 18.0 | 11.125 | 0.2219 | 655 | 15.0 |

| SWC180DH1 | 90 | 1200 | 10.763 | 600 | |||||||||||||||