Plum-shaped elastic coupling

Diaphragm coupling

Universal coupling

Tyre coupling

Slider coupling

Rigid coupling

Star-shaped (shaped) elastic coupling

Drum gear coupling

Elastic sleeve pin coupling

Elastic pin coupling

Elastic pin gear coupling

Roller chain coupling

Various coupling accessories

Water pump coupling

Expansion sleeve

Rack series

Website: www.rigid-shaft-coupling.xyz

Address: Xihuan Industrial Zone, Botou City, Hebei Province

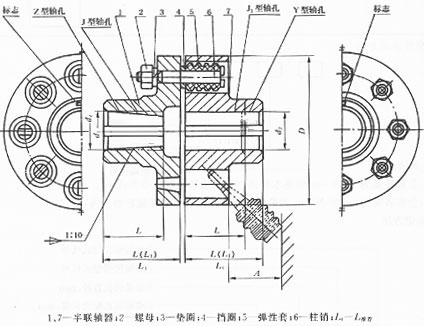

LTZ (formerly TLL type) elastic sleeve pin coupling with brake wheel

LTZ (formerly TLL type)Elastic sleeve pin coupling with brake wheelThe structure is relatively simple, easy to manufacture, no lubrication, no need to bond with metal vulcanization, easy to change the elastic sleeve, no need to move the half coupling, and has the performance of compensating the relative deviation of the two shafts and damping.

The work of the elastic sleeve is compressed and deformed. Because the thickness of the elastic sleeve is thin, the volume is small, and the elastic deformation is limited, the elastic sleeve pin coupling can compensate the axis displacement and elasticity, but the allowable compensation amount for the axis displacement is less. The elasticity is weak.The elastic sleeve pin coupling relies on the locking force of the pin group to generate the frictional moment on the contact surface, and compress the rubber elastic sleeve to transmit the torque.

LTZ (formerly TLL type) elastic sleeve pin coupling with brake wheel is suitable for small and medium power shafting transmissions with good rigidity, high centering accuracy, low impact load, and low vibration reduction requirements.

Basic performance parameters and main dimensions of LTZ (formerly TLL type) elastic sleeve pin coupling with brake wheel

|

model

|

Nominal torque Tn(Nm)

|

Allowable speed [n](r/min)

|

Axle hole diameter d1 d2 dz

|

Length of shaft hole

|

D0

|

D

|

B

|

S

|

A

|

Weight Kg

|

Moment of inertia Kg.m2

|

||

|

Y type

|

J, J1, Z type

|

||||||||||||

|

L

|

L1

|

L

|

|||||||||||

|

TLL1

|

125

|

3800

|

25 28

|

62

|

44

|

62

|

200

|

130

|

85

|

5

|

45

|

8.3

|

0.05

|

|

30 32

|

82

|

60

|

82

|

||||||||||

|

35

|

|||||||||||||

|

TLL2

|

250

|

3000

|

32 35

|

250

|

160

|

105

|

5

|

15.3

|

0.15

|

||||

|

38

|

|||||||||||||

|

40 42

|

112

|

84

|

112

|

||||||||||

|

TLL3

|

500

|

2400

|

40 42

|

315

|

190

|

132

|

6

|

30.0

|

0.45

|

||||

|

45 48

|

|||||||||||||

|

TLL4

|

710

|

2400

|

45 48

|

224

|

6

|

65

|

39.6

|

0.50

|

|||||

|

50 55

|

|||||||||||||

|

56

|

|||||||||||||

|

60 63

|

142

|

107

|

142

|

||||||||||

|

TLL5

|

1000

|

2400

|

50 55

|

112

|

84

|

|

315

|

250

|

168

|

6

|

65

|

47.0

|

1.26

|

|

56

|

|

||||||||||||

|

60 63

|

142

|

107

|

142

|

||||||||||

|

65 70

|

|||||||||||||

|

TLL6

|

2000

|

1900

|

63 65

|

400

|

315

|

8

|

80

|

92.6

|

1.63

|

||||

|

70 71

|

|||||||||||||

|

75

|

|||||||||||||

|

80 85

|

172

|

132

|

172

|

||||||||||

|

90 95

|

|||||||||||||

|

TLL7

|

4000

|

1500

|

80 85

|

500

|

400

|

210

|

10

|

100

|

127.3

|

4.04

|

|||

|

90 95

|

|||||||||||||

|

100 110

|

212

|

167

|

212

|

||||||||||

|

TLL8

|

8000

|

1200

|

100 110

|

||||||||||

|

120 125

|

630

|

475

|

265

|

12

|

130

|

304.3

|

15.00

|

||||||

|

130

|

252

|

202

|

252

|

||||||||||

|

TLL9

|

16000

|

1000

|

120 125

|

212

|

167

|

212

|

710

|

600

|

298

|

14

|

180

|

576.8

|

33.00

|

|

130 140

|

252

|

202

|

252

|

||||||||||

|

150

|

|||||||||||||

|

160 170

|

302

|

242

|

302

|

||||||||||