- Introduction to Couplings

- A detailed introduction to the drum gear coupling!

- What are the requirements for coupling guards?

- The difference between plum coupling and diaphragm coupling

- What are the characteristics of drum gear couplings?

- Frequently Asked Questions about the Installation and Disassembly of the Diaphragm Coupling

Website: www.rigid-shaft-coupling.xyz

Address: Xihuan Industrial Zone, Botou City, Hebei Province

Ever-Power brand diaphragm coupling

Everyone should be familiar with the diaphragm coupling. It originated from and was invented by a person named THOMAS in 1919. This invention added a blank to the transmission parts of mechanical products.The significance is far-reaching!Based on the above technology, our factory has produced Ever-Power brand diaphragm couplings with the trademark of this product after research and development, and its trademark has been successfully registered in the Shijiazhuang Trademark Registration Office!

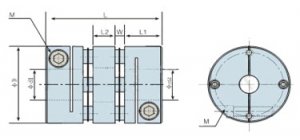

XNUMX. The structural characteristics are: several groups of diaphragms (stainless steel thin plate) are connected to the two halves of the coupling in a staggered manner with bolts. Each group of diaphragms is composed of several stacked ones. The diaphragms are divided into connecting rod type and different shapes. The whole piece.The diaphragm coupling relies on the elastic deformation of the diaphragm to compensate for the relative displacement of the connected two shafts. It is a high-performance flexible coupling with metal elastic elements.

4. Structure: 6 holes, 8 holes, 10 holes, 12 holes and XNUMX holes.

1. Diaphragm form: continuous polygonal ring shape, circular ring shape, separate connecting rod shape, spoke shape, formed diaphragm, waved diaphragm.

2. The characteristics of continuous polygonal ring and circular ring: Each coupling is composed of several diaphragms of equal thickness. The outer edge of each piece is arc-shaped, which has better elasticity, simple shape, convenient processing, but poor elasticity. In addition, the elasticity with a small number of sides is better than the elasticity with a large number of sides, but if the number of sides is too small, the stability will also be reduced. When running in one direction, only half of the ring sides carry the transfer torque.

3. Separate connecting rod shape feature: Each diaphragm is composed of a single thin rod to form a polygon. The rod has a simple shape and is convenient to manufacture, but requires the pitch of each hole. Its working performance is basically the same as that of a continuous polygonal ring, but the strength and speed are lower. Low, suitable for occasions where the coupling size is restricted.

XNUMX. Divided by material: steel diaphragm coupling, aluminum alloy diaphragm coupling; according to internal structure: hinged diaphragm coupling, integral diaphragm coupling; according to length: single diaphragm , Double diaphragm, etc.

2. Service life: The service life of diaphragm couplings on the market is generally about one year: Ever-Power brand diaphragm couplings can guarantee a service life of XNUMX years.It does not require lubrication, has a compact structure, high strength, long service life, no rotation gap, and is not affected by temperature and oil pollution. It has the characteristics of acid resistance, alkali resistance and corrosion resistance.

XNUMX. Scope of application: It is suitable for shafting transmission in high temperature, high speed, and corrosive medium conditions. It is widely used for shafting transmission of various mechanical devices, especially for machine tool transmission power, servo motors, and diaphragm couplings. .Re-water pumps (especially high-power, chemical pumps), fans, compressors, hydraulic machinery, petroleum machinery, printing machinery, textile machinery, chemical machinery, mining machinery, metallurgical machinery, aviation (helicopters), high-speed power transmission systems for ships The application in has also become more common.

After that remind everyone, the key points of the selection of diaphragm coupling:

1. Each series of couplings has its own unique performance. Please select the appropriate coupling series according to the specific requirements of the mechanical product when using it.

2. After selecting the appropriate series of products, refer to the corresponding parameter table and determine the model according to the corresponding parameters.

3. Confirm the appropriate fixing method and choose according to different needs. A reasonable fixing method is the guarantee of the stability of the equipment. For details, please refer to the "Fixed coupling method" section.

4. Confirm whether the selected product meets the conditions for on-site installation. In order to avoid installation errors.

Everyone is welcome to use the Ever-Power brand diaphragm coupling. The rationality of its research and development, the rigor of production, and the three-guarantee service for any quality problems are your best choice!