- Introduction to Couplings

- A detailed introduction to the drum gear coupling!

- What are the requirements for coupling guards?

- The difference between plum coupling and diaphragm coupling

- What are the characteristics of drum gear couplings?

- Frequently Asked Questions about the Installation and Disassembly of the Diaphragm Coupling

Website: www.rigid-shaft-coupling.xyz

Address: Xihuan Industrial Zone, Botou City, Hebei Province

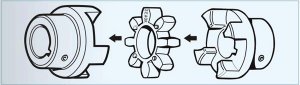

Composition and assembly of plum coupling

Plum couplingIt belongs to the category of general machinery parts. It is composed of four parts: the driving end, the driven end, the damping pad and the top wire. Its accessories include gears, sleeve connections (and the two-sided gears share a gear sleeve), rubber ring bolts Hole connection (single-sided perforation and double-sided cross perforation), plum blossom pad butt connection, nylon rod hole connection, and gears directly drive the machine.The matching hole of the half coupling and the shaft can be made circular.It can be used to connect two shafts (the driving shaft and the driven shaft) in different mechanisms to make them rotate together to transmit torque mechanical parts.

When assembling the quincunx coupling, clamp the petals of the quincunx-shaped elastic member on the end face of the two halves of the coupling. The convex teeth are staggered and inserted into the tooth side space formed by the high-speed and heavy-duty power transmission in order to work in the coupling. It plays the role of buffering and damping vibration.Strictly ensure the coaxiality of the two axes, so that no unilateral load is generated during operation, so as to maintain balance and reduce vibration. Different types of installations require 0.2 concentricity.Under normal circumstances, it is just fine to loosely match and then tighten the screws. You can also choose a plum coupling with a keyway!It is also connected with a key to the motor, screw, or other shaft end, even if you do not tighten the screw, it will not loosen.

I would like to remind everyone that the operating temperature range is -35 degrees to +80 degrees, the short-term operating temperature can reach 100 degrees, and the nominal torque range transmitted is 16 to 25000 N/m.According to the previous steps, you can quickly complete the installation of the plum coupling!