Product CategoriesProduct Classification

Plum-shaped elastic coupling

Diaphragm coupling

Universal coupling

Tyre coupling

Slider coupling

Rigid coupling

Star-shaped (shaped) elastic coupling

Drum gear coupling

Elastic sleeve pin coupling

Elastic pin coupling

Elastic pin gear coupling

Roller chain coupling

Various coupling accessories

Water pump coupling

Expansion sleeve

Rack series

Latest newsNews

- Introduction to Couplings

- A detailed introduction to the drum gear coupling!

- What are the requirements for coupling guards?

- The difference between plum coupling and diaphragm coupling

- What are the characteristics of drum gear couplings?

- Frequently Asked Questions about the Installation and Disassembly of the Diaphragm Coupling

Contact information

Website: www.rigid-shaft-coupling.xyz

Address: Xihuan Industrial Zone, Botou City, Hebei Province

Date: 2013-08-03 Click: 93 times

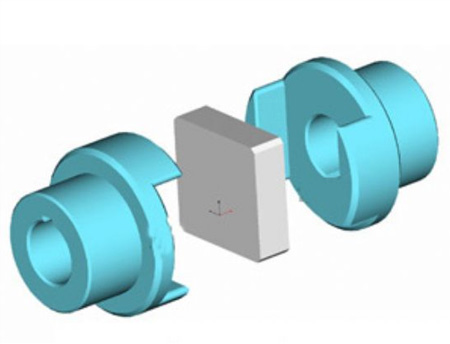

The structure of the slider coupling is similar to that of the cross slider coupling. The difference is that the middle cross slider is a square slider, and the middle slider is used to half the coupling ends on both sides of the slider.

Date: 2013-08-03 Click: 148 times

The SL cross slider coupling is also known as the metal slider coupling. Its slider is circular and made of steel or wear-resistant alloy. It is suitable for transmissions with low speed and large transmission torque.

Date: 2013-08-03 Click: 106 times

The GY flange coupling has a simple structure and is easy to use. It can transmit large torque, but it cannot cushion and absorb vibration.It divides the two half couplings with flanges with ordinary flat keys

Date: 2013-08-03 Click: 92 times

The XL type star elastic coupling has the properties of compensating the relative deviation of the two shafts, cushioning, shock absorption, and wear resistance. It is suitable for general occasions. The transmission torque is 20-35000.NM and the working temperature

Date: 2013-08-03 Click: 66 times

Star-shaped elastic coupling, the radial movement of the star-shaped elastic coupling due to centrifugal force during high-speed operation will accelerate its wear and tear, and a shell is added.In addition to being able

Date: 2013-08-03 Click: 56 times

The GⅠCLZ drum gear coupling has the ability to compensate for axis deviations in the radial, axial and angular directions. It has a compact structure, a small gyration radius, a large carrying capacity, and a transmission

Date: 2013-08-03 Click: 116 times

When the gear coupling is working, the two shafts produce relative angular displacement, and the tooth surfaces of the internal and external teeth periodically slide relative to each other in the axial direction, which will inevitably cause tooth surface wear and power consumption.